The Communication Hub for

the Wind Energy Industry

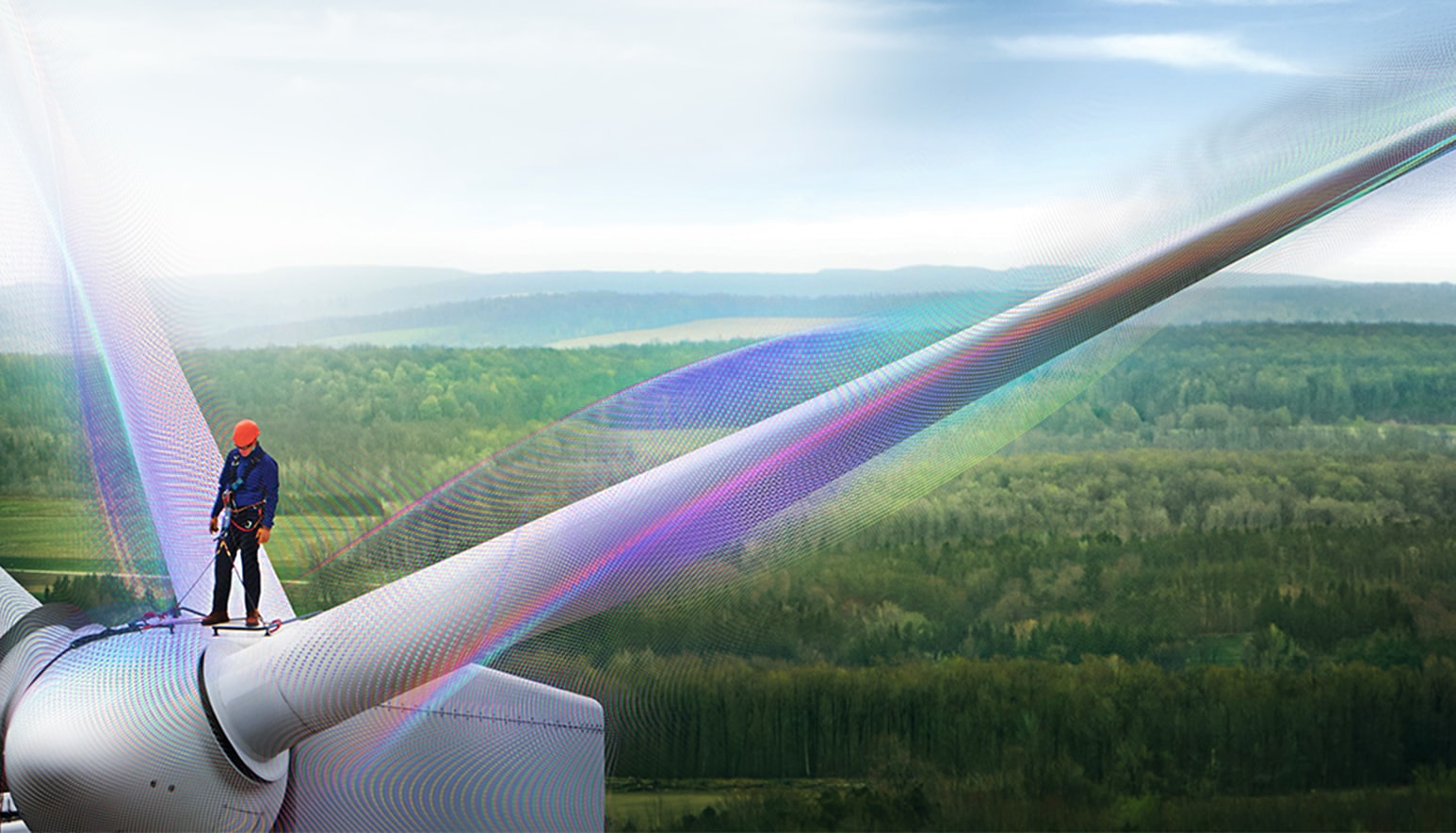

Wind Turbine Oil – Taking wind turbines to new heights

If you own, operate or service wind turbines you know that downtime costs – and costs a lot.

Wind turbine lubricants need to last as long as possible, offering excellent oxidation and shear stability, whilst protecting key turbine components such as main bearings from failure, and gears from micropitting.

Our experienced field engineers and industry-leading used oil analysis service, Signum℠ Oil Analysis, has meant we have been at the forefront of developments in the wind energy sector for over 30 years.

Introducing new, Mobil SHC™ Gear 320 WT with 7 year warranty

New, long life advanced wind turbine gear lubricant, especially formulated to resist micropitting of modern, case hardened gearing and can operate in both high and low temperature environments. We’re so confident in the durability of Mobil SHC Gear 320 WT gear oil that we offer a 7 year extended warranty†.

Proven in the wind sector

Gearboxes in wind turbines operating in North Sea wind farms such as Alpha Ventus, Borkum West and Thornton Bank are protected by high performance Mobil SHC™ gearbox oil, including Mobilgear .

In fact, is the initial-fill gear oil of choice for many of the world’s top wind turbine builders, protecting more than 40,000 wind turbine gearboxes worldwide.

Our engineers have developed specialist wind turbine greases such as to give the main, pitch and yaw bearings on wind turbines excellent wear protection, ease turbine start-up at low temperature, and extend re-greasing intervals – all reducing service costs.

Innovative wind lubricant technology

Mobil SHC™ Gear 320 WT

- Industry leading seven-year warranty

- Long drain intervals help reduce downtime

- Exceptional protection even in extreme conditions

- Resistance to micropitting and scuffing

Mobilgear SHC™ XMP 320

- Five-year warranty

- Long oil life minimizes need for maintenance downtime

- Excellent gear oil bearing wear protection

- Outstanding stability in presence of water contamination

Mobil SHC™ Grease 460 WT

- Wide application temperature ranges

- Excellent performance in hostile aqueous environments

- Reliable lubrication of bearings

- Outstanding protection against wear, rust and corrosion

Signum℠ Oil Analysis

Our industry leading Signum Oil Analysis program delivers the full spectrum of analytics on your Mobil-branded lubricants, which no other program can provide.

Find out how over 100 years of working closely with equipment builders and our extensive knowledge of international standards help make our data even more valuable for you. Through our patented processes, we continue to be a leader in oil analysis technology, providing you with reliable predictive information, as well as recommended action steps and even on-site support from our engineers.

Find out more about Signum used oil analysis.

Don’t let downtime cost your business – Book an appointment or get in touch with our technical helpdesk.

Mobil SHC™ Gear 320 WT – Introducing the latest wind turbine gear oil with 7 year warranty†

- Designed for long lubricant and equipment life

- Exceptional cold climate performance

- Approved for aquatic non-toxicity (per IMO 493/02)

Recent technical articles published in Wind Energy Network: